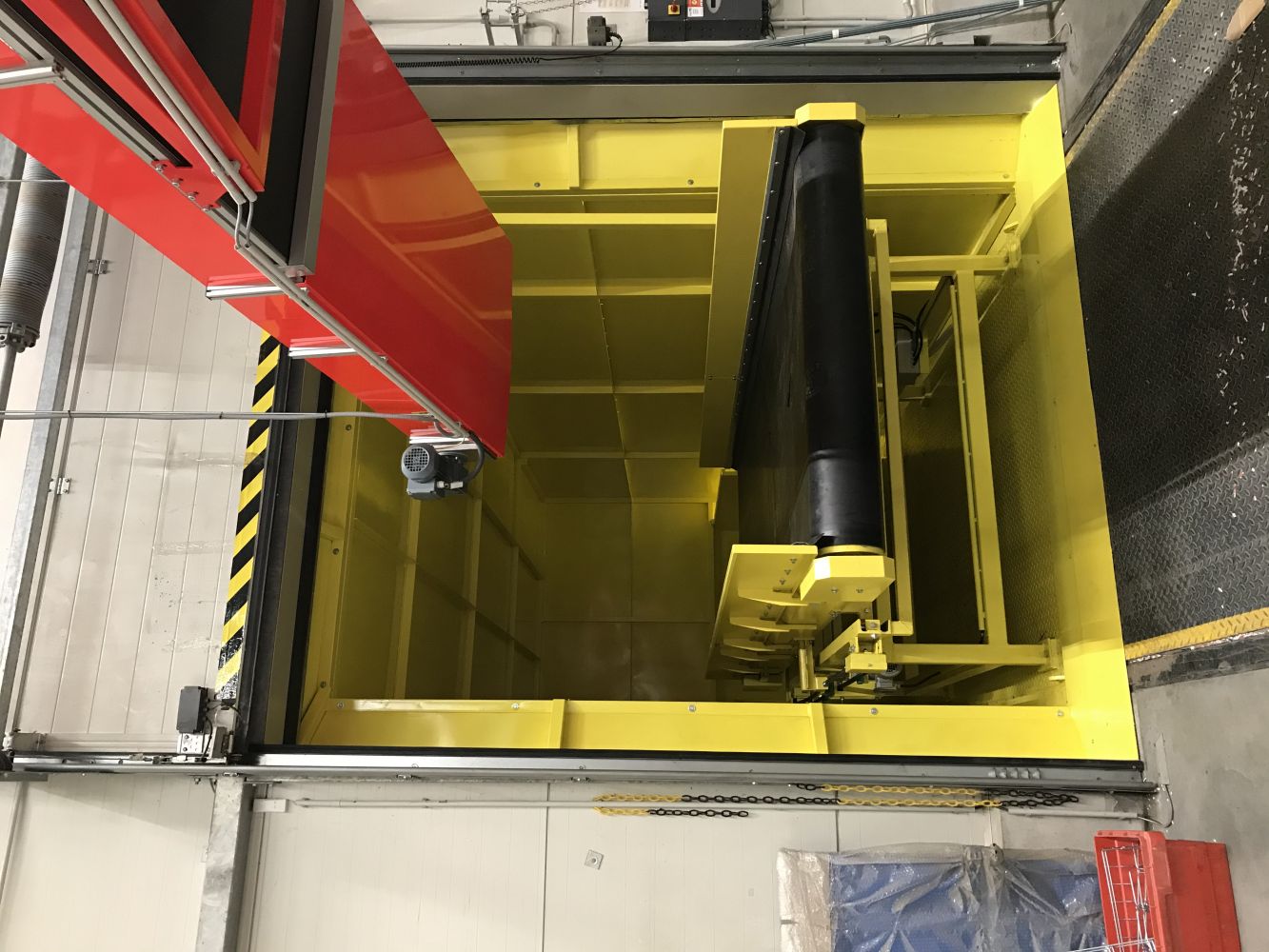

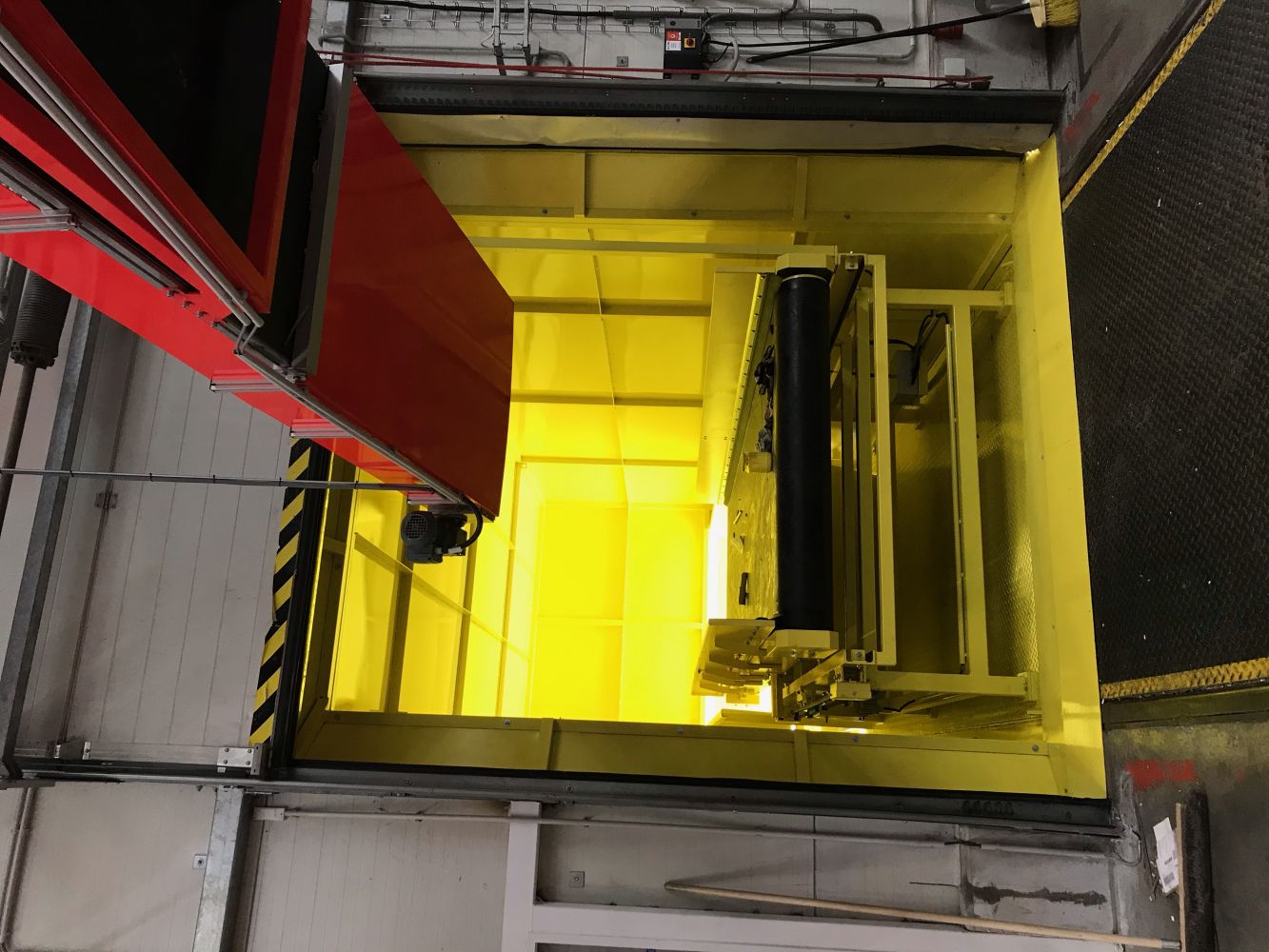

A COMPREHENSIVE SOLUTION AND ACCESSORIES

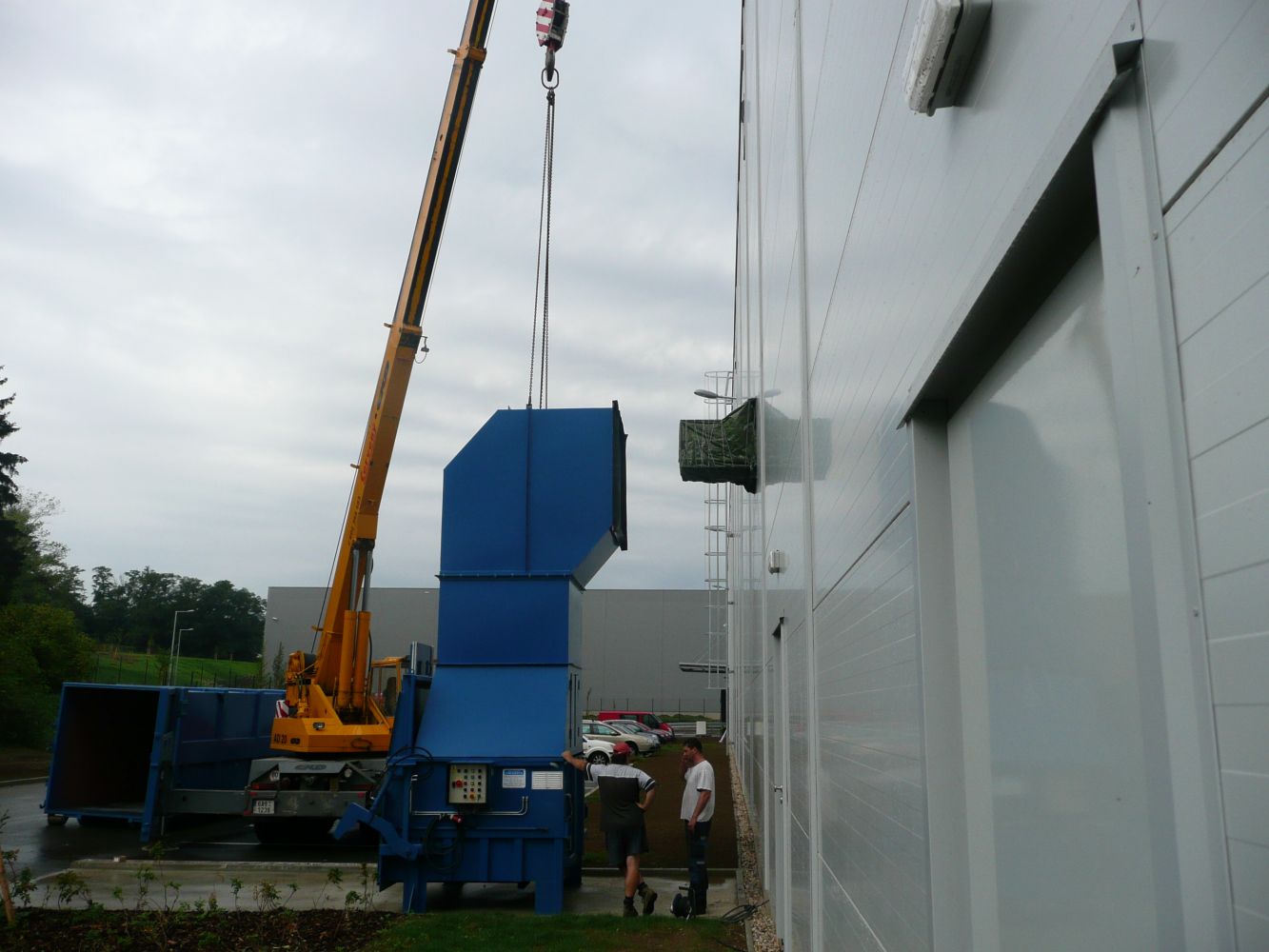

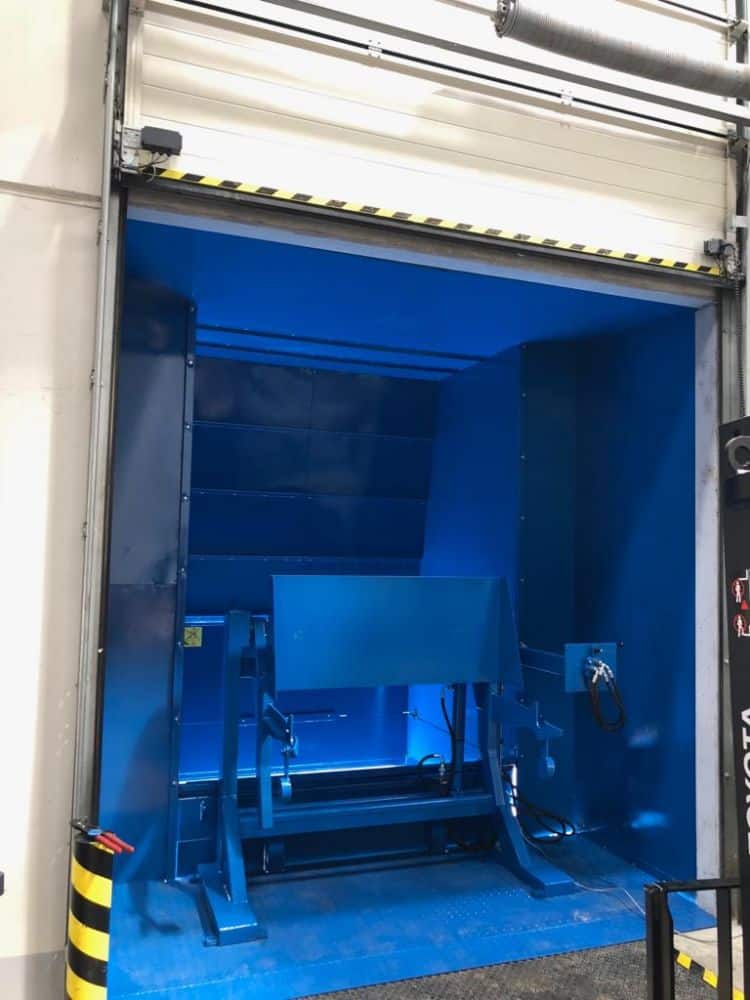

We can design a comprehensive waste solution, including the provision of pressing technology, loaders, safety elements and other accessories, as required by the customer.

A COMPREHENSIVE SOLUTION AND ACCESSORIES

We can design a comprehensive waste solution, including the provision of pressing technology, loaders, safety elements and other accessories, as required by the customer. Our years of experience and excellent feedback from our customers helps us continuously improve our solutions.

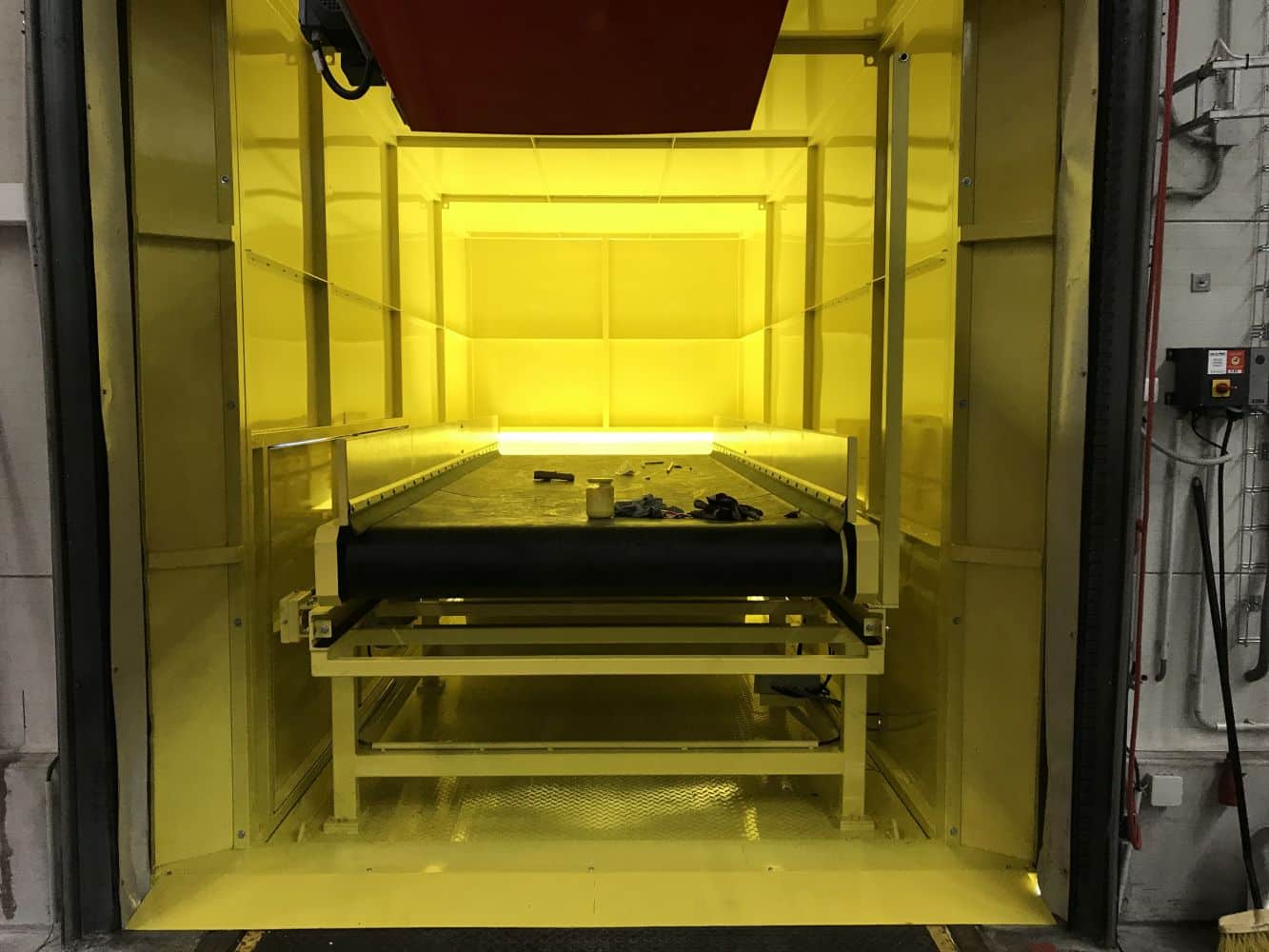

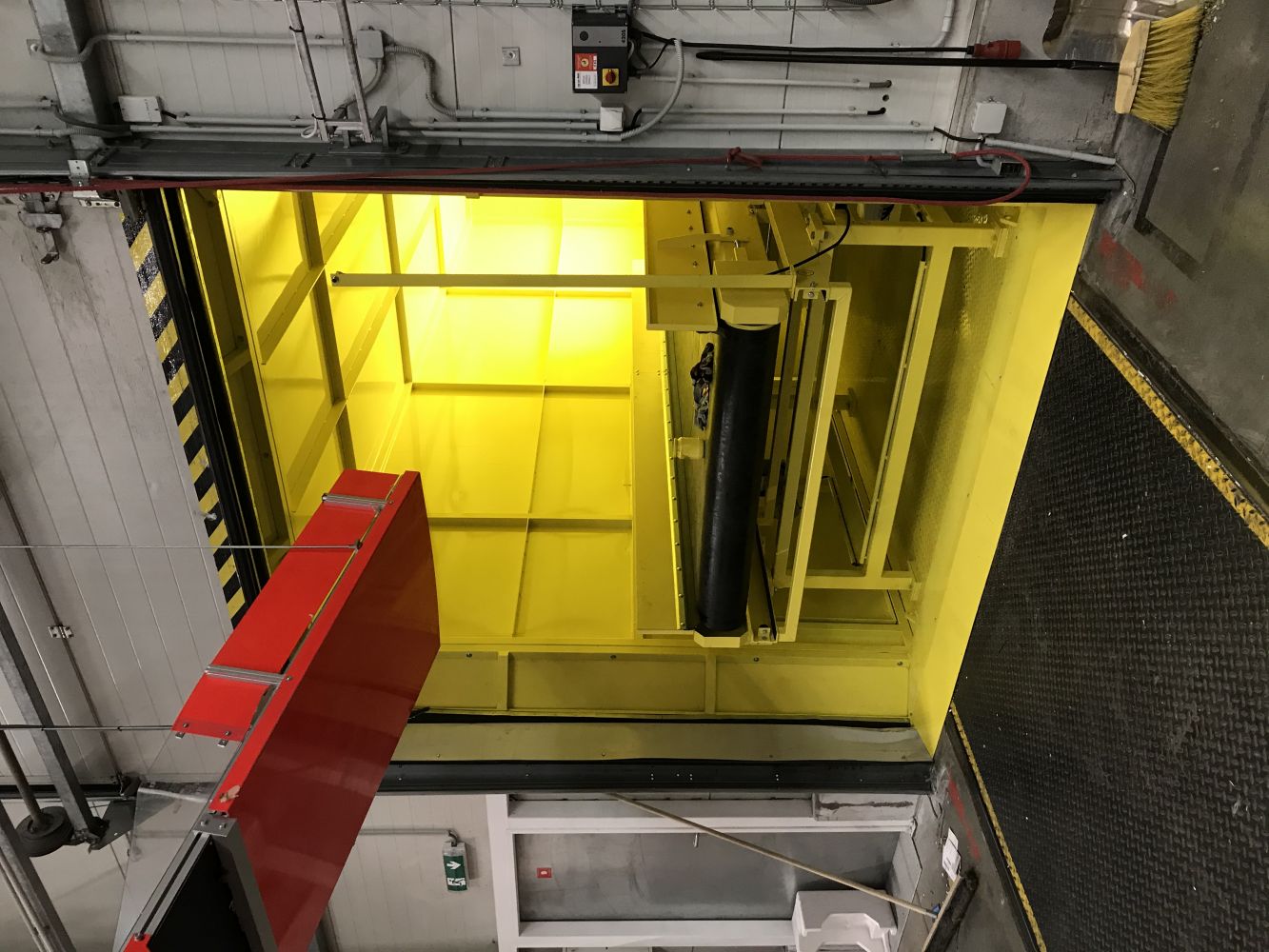

Various types of tubes, ramps, platforms, roofs and accessories are some of the most common solutions. Custom production allows us to adapt each of our machines to the customer’s precise requirements. We can adapt the dimensions of presses as well as the performance characteristics of the hydraulic unit.

We offer a wide range of accessories and control and safety elements along with our presses.

Basic accessories

- Remote control – remote control is an important element of presses that have a ramp or tube. It allows comfortable control and signalling.

- Remote control on a bar – rotary control that can be placed by the ramp to eliminate the need to disconnect the mobile press during each collection, making the press universal and suitable for use in any operation.

- Hopper lid – a lockable hopper lid with a gas strut on each side

- Raised hopper – a hopper adapted to the customer’s needs

- Raised side panels – side panels that ensure smooth pouring of material into the press hopper

- Platform – a platform firmly attached to the press; it can be extended during operation, allowing the operator to comfortably access the hopper.

- Runways for stationary presses – for comfortable, safe connection of a container to the press

- Steel floor – if the layout and the base do not allow concrete footing to hold the stationary press, this floor is the best solution. The press is firmly attached to this floor.

- GSM module – a module that sends an SMS alert to the pre-set telephone number when the container is 80% and 100% full

- Safety light curtain – a safety element that prevents the press or tipper from starting up when the operator is nearby

- Diffusion sensor – a sensor that starts the pressing cycle when material is thrown into the hopper

- Lifting bale bar on the door – allows retraction of the mobile press container on both sides

- Connection to a machine monitoring system

- Different types of ramps, platforms, tubes

We can design accessories and make adjustments according to the customer’s requirements.