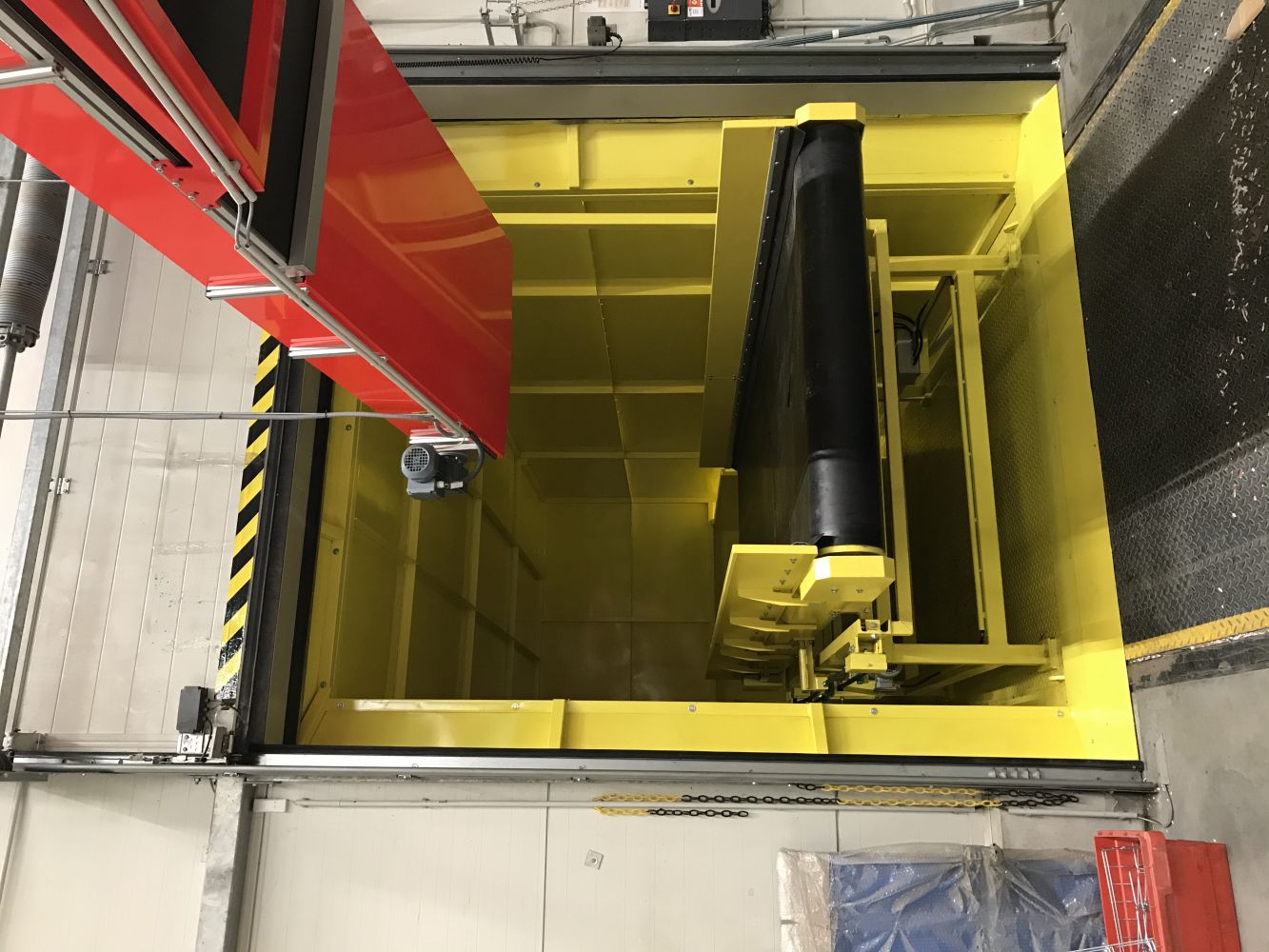

STATIONARY PRESS VSP 70

The VSP 70 press is designed for maximum performance at full load and with a large amount of waste. This press has a stronger hydraulic unit, a reinforced structure and a large hopper.

STATIONARY PRESS VSP 70

The VSP 70 press is designed for maximum performance at full load and with a large amount of waste. This press has a stronger hydraulic unit, a reinforced structure and a large hopper. It is suitable for operations that generate a large amount of waste. It is best connected to a conveyor system for continuous filling, or for filling forklifts.

Stationary press VSP 70 is firmly screwed onto a concrete base with anchor bolts. All functions of the container are controlled by buttons on the control panel and a programmable module. The runways in front of the press allow seamless connection of an connection container to the press. The press can be placed on a steel floor if the terrain is uneven.

VSP 70 LR (manual connection). Once the container is pushed up against the press, the operator anchors the press hooks into the latches and fastens the container to the press with a ratchet screwdriver.

VSP 70 LH (automatic connection). This button is used for automatic connection through hydraulically controlled arms. The button also opens the shield located on the secondary container and starts the pressing cycle. The number of cycles is set according to the customer’s requirements.

When the container is 80% full, the green light on the panel lights up. If requested by the customer, an audible alarm can also be installed. When the secondary container is 100% full, the red light on the panel lights up and the pressing stops. A GSM Module can also be installed on the press to signal faults and when the press is full, or it can be connected to the machine monitoring system.

Connection containers come in standard sizes of 20 and 36 m3 (VPS).

Optional accessories for stationary press VSP 70

- durable hopper (with a crushing frame for filling forklifts)

- flexible hydraulic mount

- oil cooling

- oil heating

- optical startup sensors

- integrated, ramp or mobile loader

- connection for conveyor belts

- machine monitoring and remote management system

- large hopper for dumping waste from vehicles

- tall hopper